3D printing of bio-based plastics on an industrial scale

New digital manufacturing technology enhances competitiveness and environmental friendliness in the boat industry.

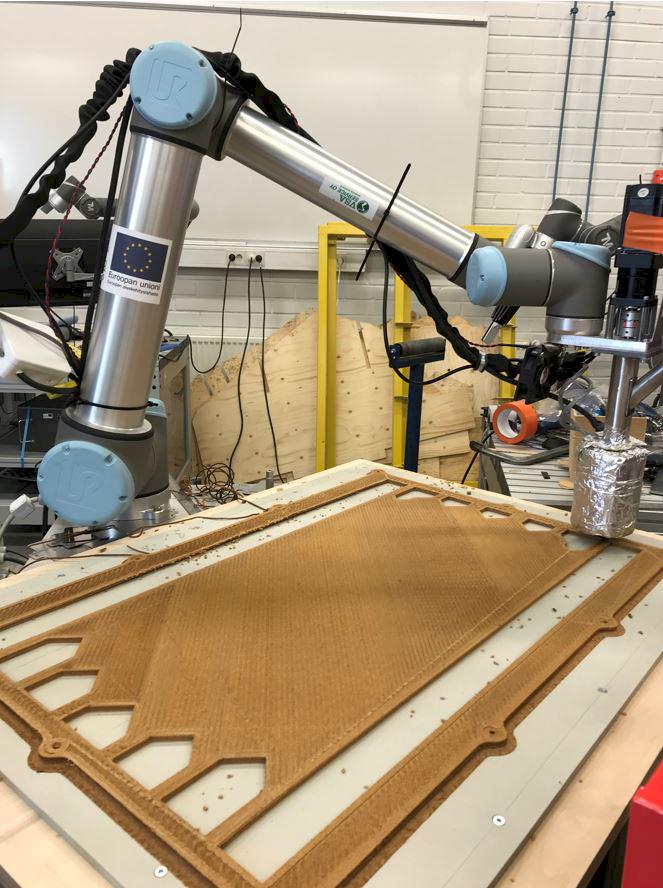

Competence and application of robotics in different stages of production is bringing new innovative production methods to the market. One example is manufacturing of large plastic parts using the 3D printing technology, in which a digital model that is a 3D file is produced into a physical piece using a 3D printer. 3D printing represents the most advanced form of digital production.

However, the method is new and its introduction in companies in the region requires some more testing and understanding of the benefits of the technology. In the new project called “VENEPRINT – Additive Digital Manufacturing in the Boat Industry”, a pilot-scale printing environment will be established at Centria University of Applied Sciences. The potential of industrial 3D printing will be highlighted by demonstrating its suitability for printing structural parts of boats.

The materials used in the 3D printing method are recyclable, and there are also bio-based materials suitable for printing available on the market. Currently, most of the materials in boats are fiber-reinforced polymers, which are problematic to recycle. Centria’s strong expertise in plastic and composite materials is used in the selection of new materials that are suitable for production and also easy to recycle.

The impact of a successful project is wide and varied. The project will create a basis for new investments by companies. With the introduction of 3D printing, the boat industry is being reformed, and a new, more modern technology is attracting new employees to the industry. The products of companies also generate added value through customization. New recyclable materials and a reduced waste stream improve the sustainability of products and production as well as the image of companies. Ensuring the recyclability of products at the design stage can also open up new business opportunities based on the circular economy, such as boat repair, return or purchase of boats, dismantling and material reuse in the boat industry.

Project duration October 2021 – August 2023

The project budget amounts to € 280,400 and is funded by the Regional Council of Central Ostrobothnia and the EU’s Sustainable growth and jobs 2014-2020 – Finland's structural funds programme.